|

CORE

SERVICES > CNC PLASMA CUTTING & MACHINING

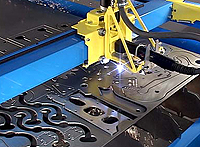

CNC

Plasma Cutting & Machining

Plasma cutting is a process that is used to cut

steel and other metals of different thicknesses (or

sometimes other materials) using a plasma torch. In

this process, an inert gas (in some units,

compressed air) is blown at a high speed out of a

nozzle; at the same time an electrical arc is formed

through that gas from the nozzle to the surface

being cut, turning some of that gas to plasma. Plasma cutting is a process that is used to cut

steel and other metals of different thicknesses (or

sometimes other materials) using a plasma torch. In

this process, an inert gas (in some units,

compressed air) is blown at a high speed out of a

nozzle; at the same time an electrical arc is formed

through that gas from the nozzle to the surface

being cut, turning some of that gas to plasma.

Plasma is an effective means of cutting thin and

thick materials alike. With the added feature of

pre-existing shape libraries, and digital storage,

we can receive and store AutoCAD files for repeat

orders. This ensures a continuous and quick

production process that minimizes the cost of

multiple set-ups.

Our dedicated cutting department is manned by a team

that has mastered the cutting business through years

of experience.

Plasma Cutting Capabilities

CNC Machining

-

CNC Machining is the process by which material

is removed from a workpiece with Computer

Numerical Control (CNC) equipment that cuts away

unwanted material.

-

Machining is possible on virtually any material.

Parts are machined directly from your 3D CAD

models.

|